Objective :

♦ Understanding of the Product and Its Criticality

Examples :

♦ Product Range

♦ Product Usage (Real Sample)

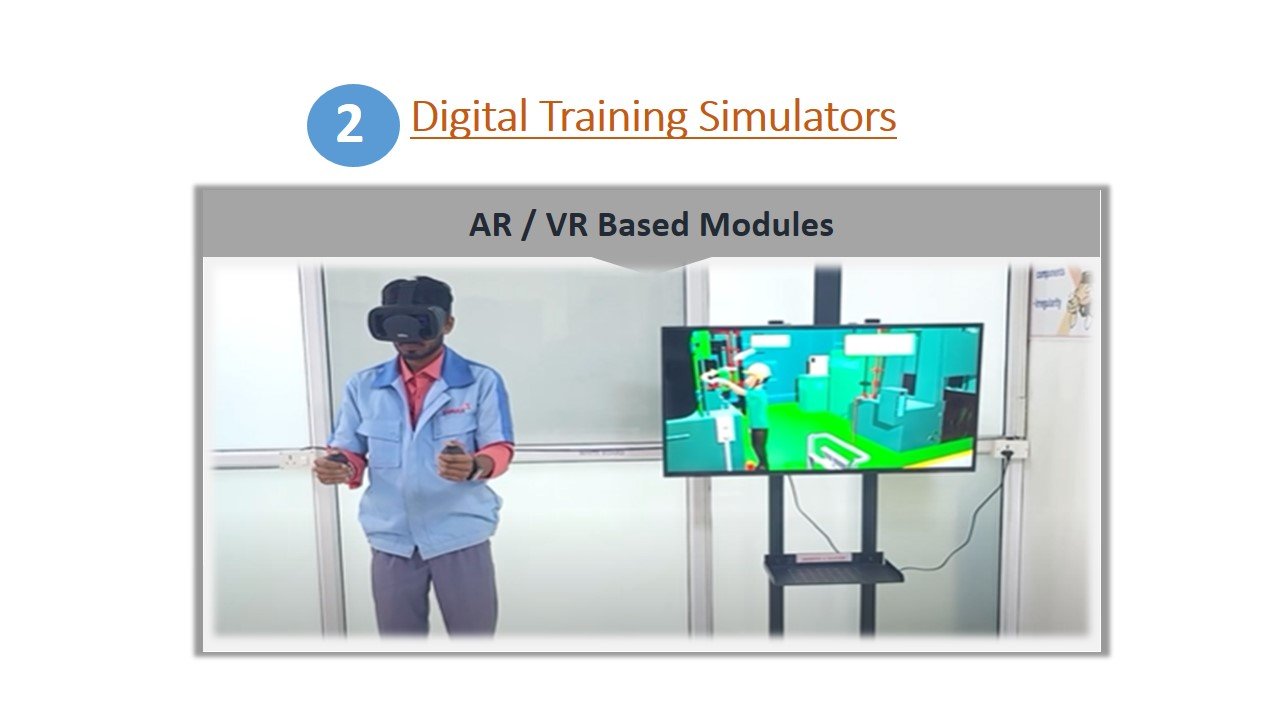

♦ Product Usage (Simulation)

♦ Part – Product Matrix

♦ Criticality of Product

♦ Similar Product in Market

♦ Simulation (Virtual Reality Base)